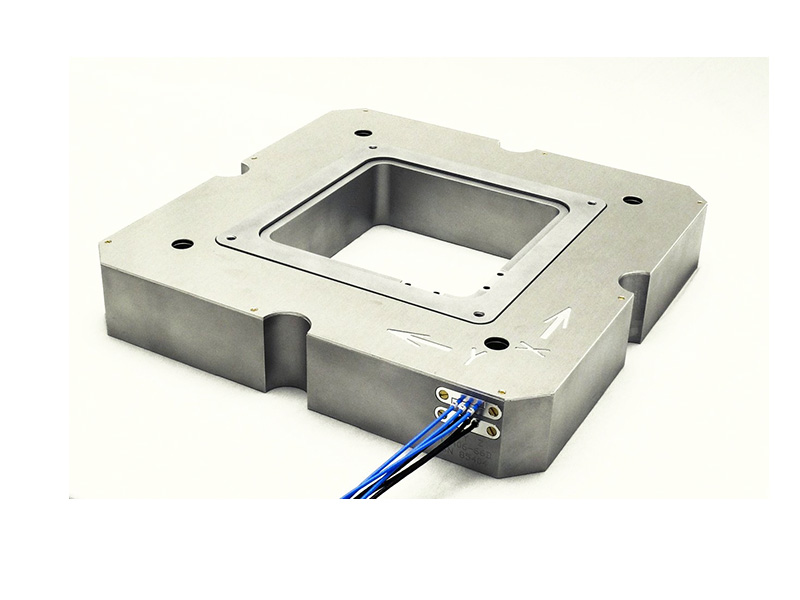

TRITOR 320 – Description

The capability to move loads up to 20 kg make the TRITOR 320 one of the most robust piezo driven 3D positioning stages available on the market. The stage can be equipped with an integrated feedback sensors for closed-loop control. The unique design of the flexure-hinges allow for excellent usability with zero friction.

High stiffness, in combination with excellent straightness of motion, makes the TRITOR 320 ideal for high precision positioning in the nanometer range of heavy objects such as wafer chucks, bonding tools, and pick & place platforms.

Piezoelectrical actuators can act much faster, and with a higher accuracy to a signal change, than any motorized drive available. The resolutions of piezoelectrical actuators are only limited by the signal noise of the control system. Therefore, these piezo solutions are an excellent choice for positioning applications in fiber alignment, optics, wafer handling, medical equipment, etc. Each axis can be controlled separately in closed loop mode. An integrated sensor system is an available option that guarantees accuracy in the nanometer range.

Dynamic scan applications are a typical utilization of TRITOR stages. The simultaneous motion, available in X, Y and Z directions, offers a large degree of freedom. All stages of the TRITOR series can be made with special materials for unique vacuum or cryogenic applications.

Technical Data

| UNIT | TRITOR 320 | TRITOR 320 CAP | |

|---|---|---|---|

| Part # | T-406-70 | T-406-76 | |

| Axes | X, Y, Z | X, Y, Z | |

| Motion in Open-Loop (±10%)* | μm | 50/50/400 | 50/50/400 |

| Motion in Closed-Loop* | μm | – | 40/40/320 |

| Resolution** (Open-Loop Mode) | nm | 0.1/0.1/0.8 | 0.1/0.1/0.8 |

| Resolution** (Closed-Loop Mode) | nm | – | 1 |

| Dimensions (L x W x H) | mm | 320 x 320 x 55 | 320 x 320 x 55 |

| Weight | g | 8000 | 8000 |