Improve Your Micro-Assembly Process

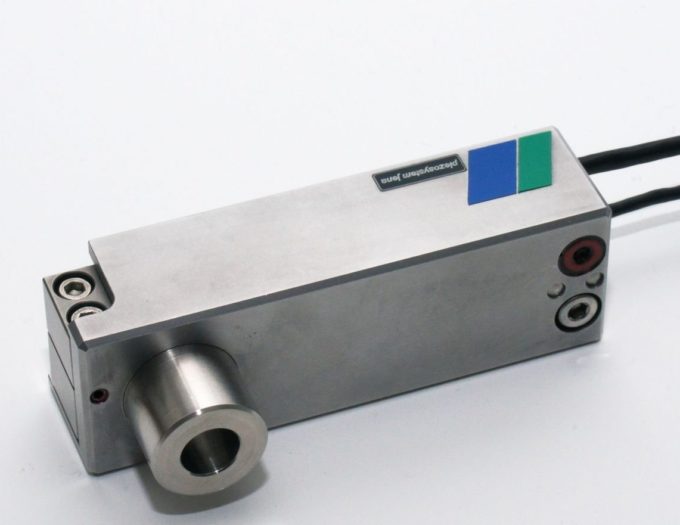

MICI micrometer screw positioners can be used in many applications including improving the positioning-resolution of linear stages. They have high resonant frequencies which allows for dynamic operation and the precise movement of heavy loads.

Pre-adjustment is done by the measuring screw and the final fine adjustment is made by the MICI element. Typically, the piezo driven system generates forces up to 200 N. The resolution is down to the sub-nm range.

The major advantage of the MICI system is that it can be installed into an existing system easily. Your system can be upgraded to achieve sub-nm resolution.

The MICI 80 and MICI 200 elements are compatible with micrometer drives model 152-401, 152-402 and 197-101 from “Mitutoyo.

Specifics:

In design and resonant frequency the MICI systems offer highly desired features. The piezoelectrical drive systems of the MICI series have been developed with a compact design. They offer motion from 80 µm (MICI 80) up to 250 µm (MICI 200) in open-loop. Based on their sophisticated flexure hinge design, the resonant frequencies range up to 990 Hz for the MICI 80. Additionally, the MICI 80 is designed for moving high load masses. A load of up to 20 kg can be adjusted with precision. As an option, a positioning sensor guarantees extremely high positioning stability and reproducibility.

MICI Series Characteristics:

- Motion up to 250 µm

- High precision adjustment of linear positioner

- Motion without mechanical play

- Precise adjustment of heavy loads

- MICI 80 and 200 are compatible with micrometer drives 152-401, 152-402, and 197-101 from “Mitutoyo

- Cable length = 1 meter

- LEMO OS.302, and D-Sub 15 connectors