Production Facility

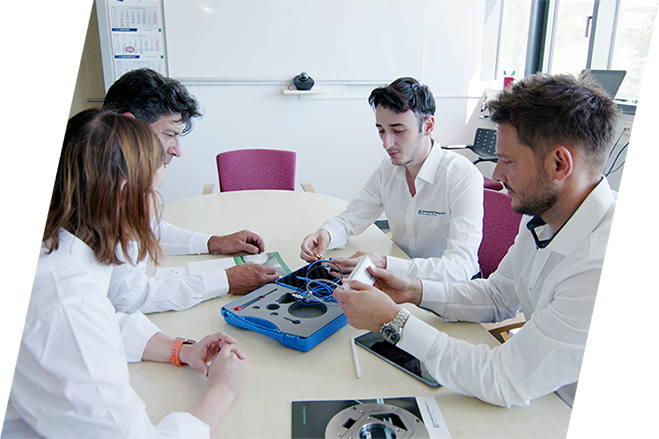

As an OEM supplier the production facility where components are manufactured is extremely important to us – and to clients. Our manufacturing building was designed to be a manufacturing facility, and thus it was configured correctly from the start.

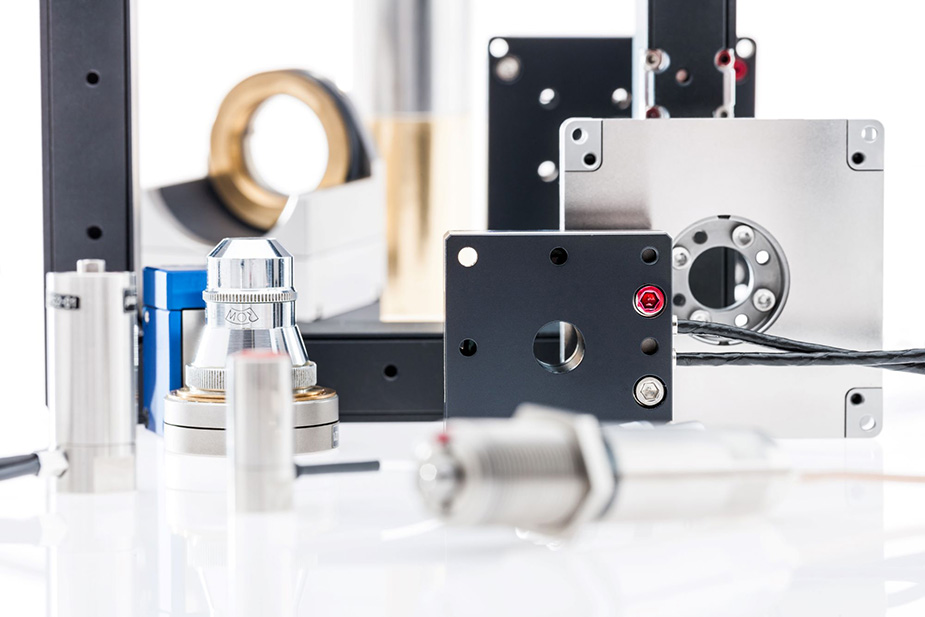

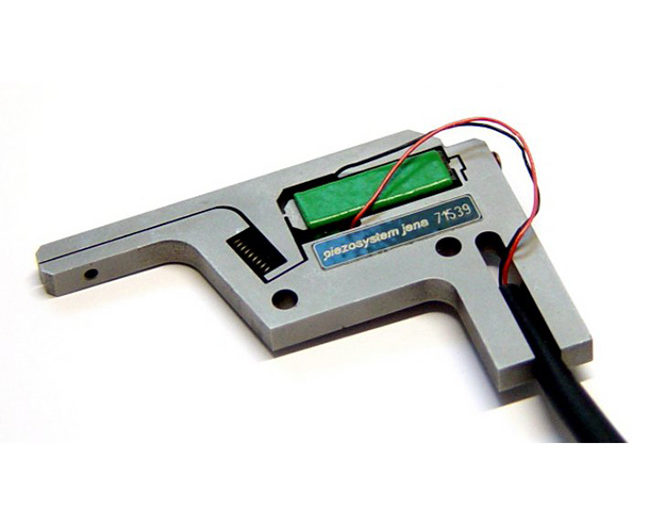

Within the production facility, the piezosystem jena team of highly trained operators build, calibrate, and test each piezoelectric actuator and amplifier by hand. With state-of-the-art flow boxes, ISO Class 7 clean space conditions provide customers with clean, reliable systems that meet the highest criteria for cleanliness for our semiconductor industry partners.

In vibrationally isolated testing spaces, each actuator is calibrated with double and triple beam interferometers to ensure each system operates to the product specifications. All actuators are tested and supplied with a personal hysteresis report.

As a trusted supplier, piezosystem jena has been delivering OEM components to clients for 25+ years

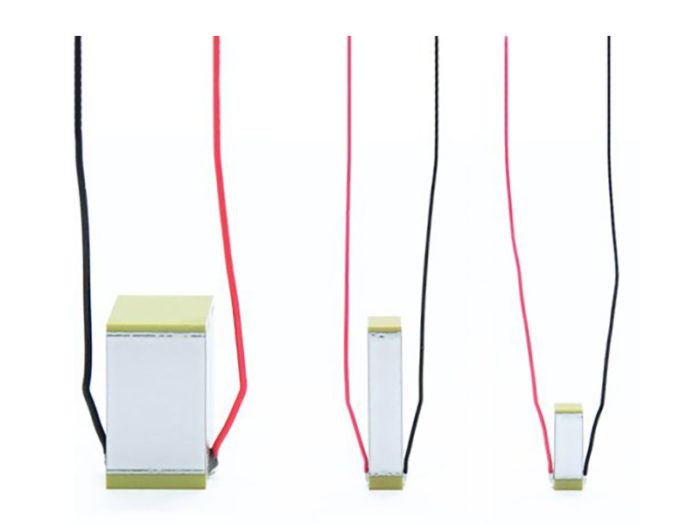

As an OEM supplier, high volume production has many meanings. High volume to one client may mean 100 units/year, and to another client 500 units/month. Cost-effective manufacturing of large scale production is possible even for demanding piezo component builds.

For over 25 years, piezosystem jena has been supplying components to manufacturers. Industries we supply with OEM grade positioning solutions:

- Semiconductor

- Optics

- Energy

- 3D Printing

- and Mechanical Engineering – among many others

About 80 percent of production at piezosystem jena is supplying industry customers with positioning solutions on a large scale. Almost all these solutions are highly customized or even developed and built from scratch. piezosystem jena works side-by-side with customers to develop and support precision solutions.