Pixel-shift is often used in industrial cameras and microscopes to improve resolution and overall image quality. Piezo stages are essential for this technique.

The quality testing and inspection industry has precise requirements for cameras and microscopes. The higher the resolution of an image, the more details can be examined and thus inspection results improve. Shorter inspection cycles play a pivotal role – time is money.

The manufacturers of industrial microscopes and integrated cameras constantly update their product lines to meet these demands. But just putting in more powerful image sensors is not enough. More and more microscope cameras also use a technique called Pixel-shift. Thanks to this method, standard resolutions of image sensors like, e.g. CMOS, CCD and FPA, can be increased multiple times. The color quality significantly improves as well.

How does Pixel-shift work?

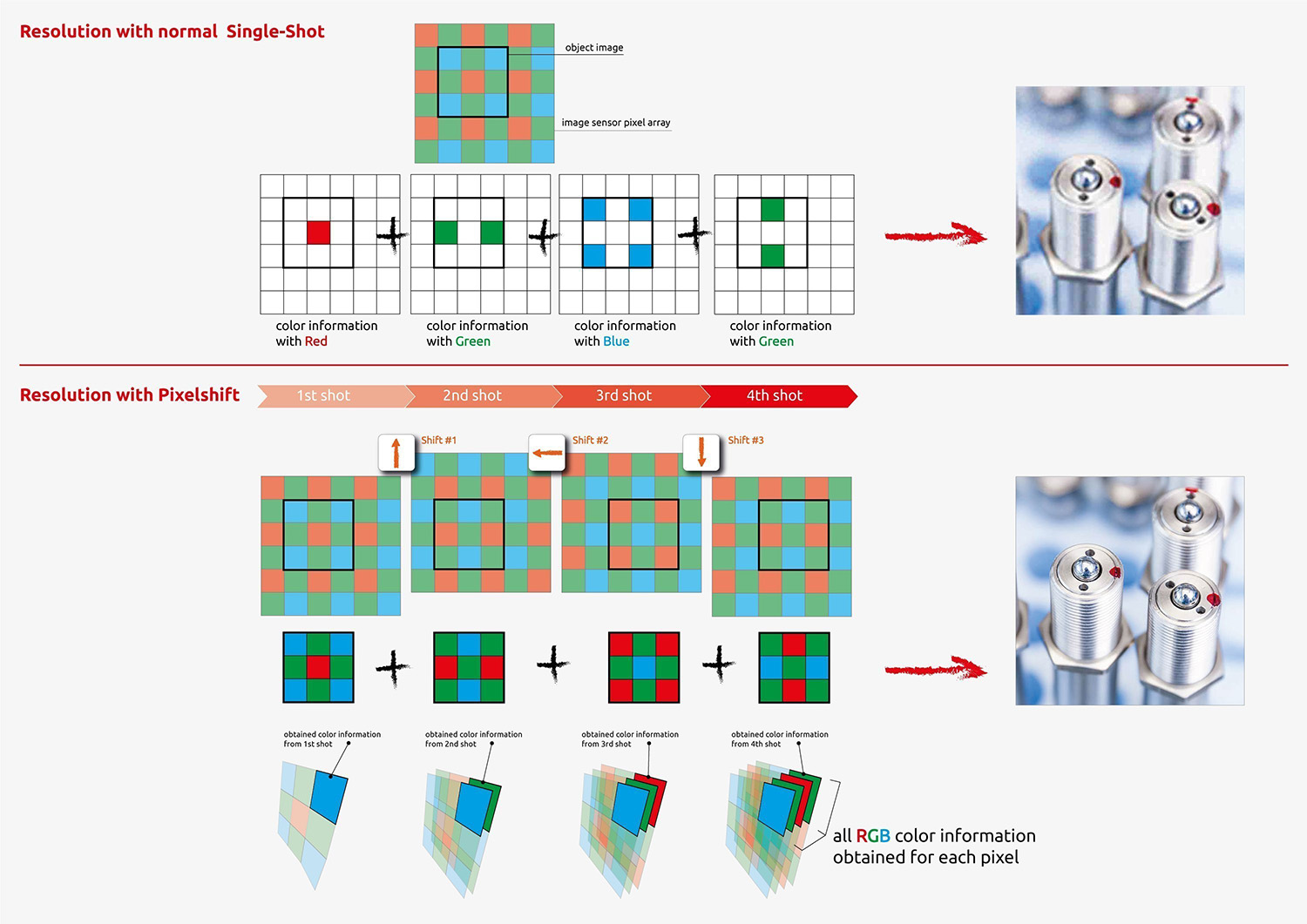

The term pixel-shift refers to a process in which an image is shot multiple times. With each shot the lens or image sensor is moved by half or a third of a pixel. On a PC or other processor all these images will be stitched into one. The result is a crisper image with a resolution multiple times higher than the original one. Resolution increases with the number of individual images – it increases four times with a shift of half a pixel, nine times with a shift of a third of a pixel and so forth. The true color of the images is not impacted by this process. Another benefit is that individual pixel defects are corrected. Overall, the efficiency of the sensor is increased through pixel-shift.

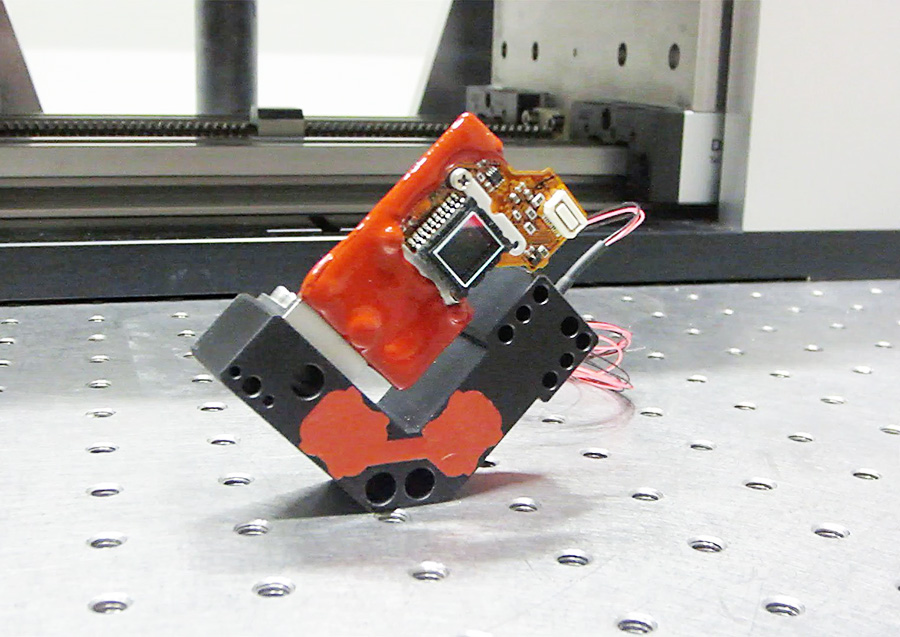

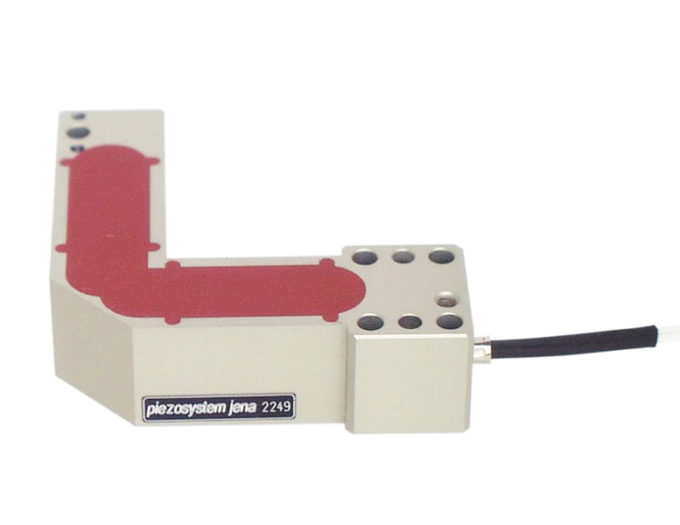

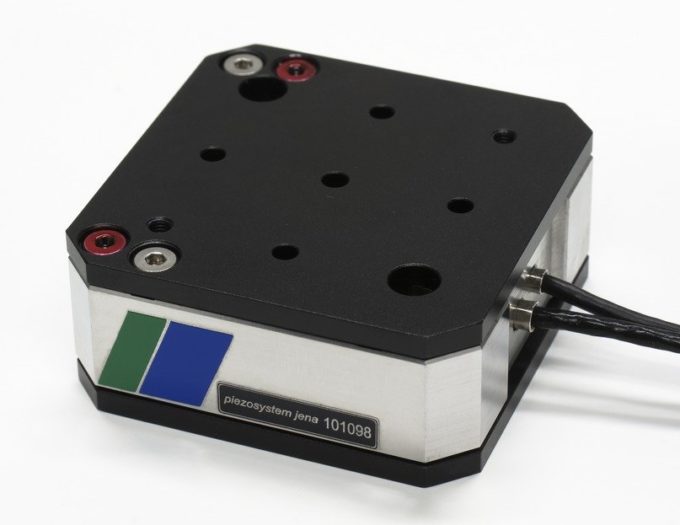

The optimal technological basis for pixel-shift is a piezo stage that shifts the image sensor or lens along the X- and Y-axes rendering multiple shots with microscopic deviations possible in the first place. Only piezo stages and actuators offer the resolutions for the required µm- shifts

An image pixel does not have a standardized size. In cameras pixel sizes can vary. Industrial cameras and microscopes often use larger image sensors with pixel sizes of <5 µm. These larger surfaces offer more light sensitivity and thus provide sharper images and more detailed results. Consumer products usually use smaller pixel sizes but also have more image noise.

Piezo stages theoretically have unlimited resolutions and are able to provide very small steps in the nanometer or sub-nanometer range. But the capacities of many displays and the computational power of many processors may limit working with higher image resolutions.

Piezo stages also provide additional benefits using this pixel-shift technique. It is not just the high resolution and precision – they also offer fast reaction times up to the microsecond range and an overall step repeatability, stability and reliability that is unmatched by other technologies.

Pixel-Shift Improvements

Which piezosystem jena systems can be used for Pixel-Shift?

With a piezo stage the “shift” can be realized in a variety of ways. The individual models of the PXY Series provides precise, highly repeatable movements along an XY- coordinate system and are ideal for the XY-shifting of an image sensor or lens. The PSH Series of tip-tilt stages can also be used. They realize the pixel-shift via angle deviations. Depending on the intention and construction method of an industrial microscope or camera, stages like the ScanXY 40 or certain models of the NanoX® series might also qualify.

To achieve high and stable resolutions with a piezo stage, a piezo amplifier with low electrical noise levels is crucial. The lower the noise level, the smaller the step widths that can be reached. This is, of course, not only important for pixel-shift but for all applications in need of micro-, nano- or sub-nanometer steps. piezosystem jena piezo controllers have extremely low electrical noise levels. The digital amplifier d-DrivePro for example, only has 0,15 mV. With such amplifiers, optimal piezo usage and control are ensured.