X, Y and Z Precise Positioning

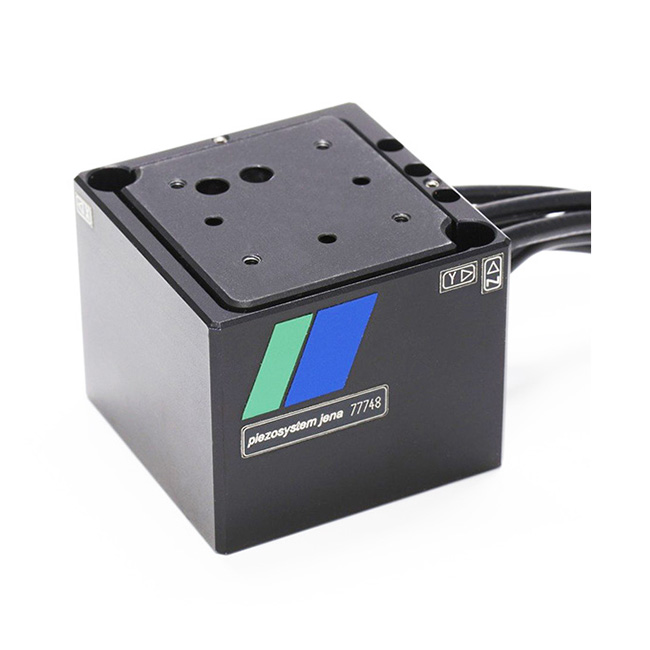

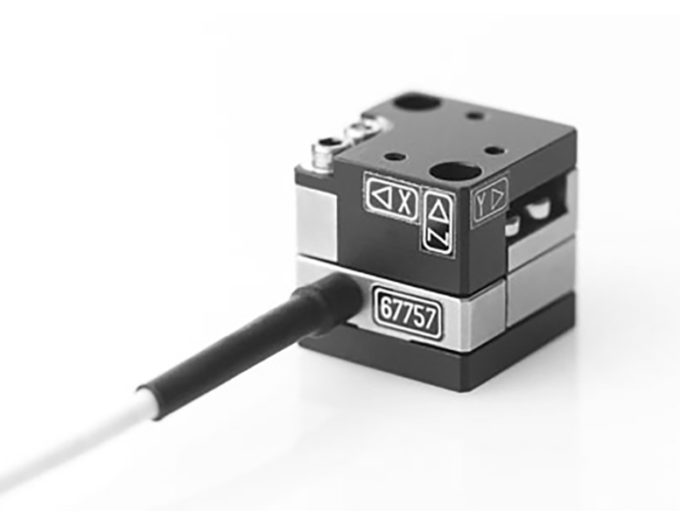

TRITOR® nanopositioners are extremely compact but offer motions of up to 400 µm in all three X, Y and Z axes. Parallel motion is achieved without mechanical play due to the system’s rigid design. As an option, integrated position control systems for overcoming the effect of hysteresis are available.

These piezo stages can be easily combined with other mechanical positioning systems, and they are well suited for various applications reaching from optical research to OEM systems.

TRITOR® elements consist of actuators integrated in a housing with internal lever transmission. Since the lever mechanism works in both directions, forces between the housing and top plate need to be avoided, as they could damage the stage.

These multi-axis positioning stages are attached by using two diagonal holes.

Mounting:

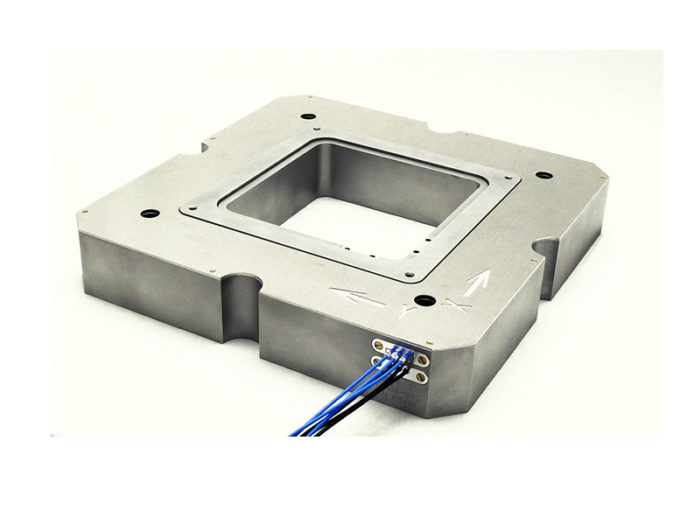

All piezo stages are constructed with a top and a bottom plate. Through holes are used for fixing the stage which is important for all dynamic applications.

On the top plate there are several pin holes and threaded holes for the mounting of external components.

Stages Characteristics:

- 3D nano-positioning stage

- Compact design

- Flexure hinge design without mechanical play

- Motion ranges in the 9 to 400 µm range

- Highest positioning resolution

- Typical applications include AFM and SFM microscopy, fiber alignment, beam steering, and semicon manufacturing