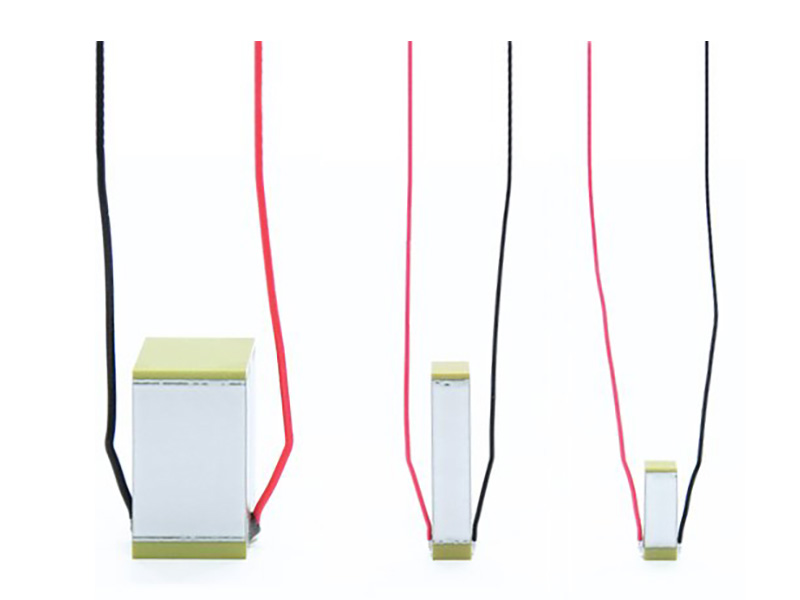

Series N Piezo Actuators – Description

Series N piezo actuators are made for industrial applications. They consist of a large number of contacted ceramic discs. The electrodes are arranged on both sides of the ceramic discs. They are specially shielded by a flexible insulation material which guarantees the highest possible dynamic performance under the toughest requirements. Based on their design, they are well suited for easy integration into specific customer systems. Special designs are made with a centrically drilled hole.

The special flexible polymer insulation guarantees the highest performance for long term applications. It gives the PZT piezo actuators proven protection against various and harsh environments. The advantage of a flexible insulation versus brittle ceramic insulation is a longer lifetime. Results show that piezo electric actuators have worked, and continue to work, under extreme conditions for over 20 years. The insulation is also suitable for use in cryogenic and vacuum environments. Additional thermal shrink tube insulation protects the cable connection point on the ceramic.

It is important not to subject the actuator tip to non-axial forces during a manufacturing process and use. The PZT multilayer stacks are not preloaded. An external preload is applied when used in dynamic applications or in applications with high acceleration forces.

The standard cable length is 100 mm. As an option, flat tungsten carbide or ball tip end plates are available. Please note that when using these actuators under cryogenic conditions (4 K), only 10% of the standard motion is available.

The Series N piezo actuators have been successfully working for more than 20 years in a vast number of applications in the fields of nano-metrology, semiconductor, material sciences and scanning applications.

Technical Data

(See Datasheet PDFs below this chart for the complete list of product variations)

| 4 Example Products | UNIT | N 2/5 | N 25/S3.5 | N 100/S5 | N 120/S10 |

|---|---|---|---|---|---|

| Part # | P-211-00 | P-217-40 | P-207-40 | P-237-40 | |

| Motion (±10%)* | μm | 2 | 30 | 103 | 123 |

| Capacitance (±20%)** | μF | 0.1 | 1.2 | 9.0 | 36.4 |

| Stiffness | N/μm | 250 | 14 | 8 | 28 |

| Resolution*** | nm | 0.004 | 0.06 | 0.2 | 0.25 |

| Dimensions – L x W x H | mm | L = 5 | 27 x 5.5 x 7.5 | 108 x 7 x 9 | 108 x 12 x 14 |

| Diameter | mm | 5 | – | – | – |